Applications

- Automobile POF system

- The application of POF in home network

- Running Ethernet Over Plastic Optical Fiber

- POF-the best choice for the last 100 meter

- Current situation of POF and technology trends

- kinds of POF

- Fiber bring up environmental protection data center

- Analysis of Step-Index Plastic Optical Fiber Bending Loss

- Polymer optical Fibers for short shorter and shortest data links

- POF and related device used in Industry

- 中国光纤市场2010年印象(一):过剩在所难免 萧条绝难出现

- 中国光纤市场2010年印象(二):过剩在所难免 萧条绝难出现

- What is U-verse?

Applications

Running Ethernet Over Plastic Optical Fiber

Plastic Optical Fiber (POF) has emerged as a low-cost alternative to traditional copper cabling in office, home and automotive networks. Continued growth for POF is estimated to be worth in excess of $1 billion a year by the end of 2008.

POF offers many benefits to the user: it is lightweight, robust, cheap and easy to install; the use of 650nm red LED light makes it completely safe and easier to diagnose as red light can be seen by the human eye. Installation is further simplified as existing mains cable ducting can be used to route the fiber without any impact from noise interference. The fact that fiber is totally immune to electromagnetic noise and emits no radiation is one of the biggest advantages in today??s complex and congested world of networking.

Differences Between Plastic and Glass Fiber:

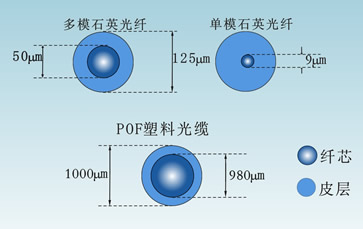

POF differs from traditional optical fiber in material and core/cladding dimensions (Figure 1). POF has a much larger core diameter compared to both Single-Mode Fiber (SMF) and Multi-Mode Fiber (MMF). Although this results in lower data rates (100s of Mbps) and lower reach, there is a big advantage in terms of cost.

The large core means the accuracy of alignment between the LED driver and fiber is less critical, to a point where even slightly damaged fiber is acceptable. Most of the expense in fiber systems today is not in the Bill Of Materials (BOM) but production set-up and alignment costs.

Figure 1. Single-mode, multi-mode and POF core/cladding diameters

Standard fiber-optic cables have a glass quartz core and cladding. POF typically utilizes a polymethylmethacrylate (PMMA) core and a fluoropolymer cladding. Glass fiber-optic cable offers lower attenuation than its plastic counterpart, but POF provides a more rugged cable, capable of withstanding a tighter bend radius.

POF Over Ethernet

POF has generally been utilized in more niche applications where its advantages outweigh the need for high bandwidth. Advances in LED technology and Vertical Cavity Surface Emitting Laser (VCSEL) technology are enabling POF to support data rates of 3Gbps and above, opening the doors to more mainstream applications.

However, for POF to become a serious alternative to copper cable networks it must be able to support Ethernet, since it is almost exclusively used as the lower layers in any office network and is beginning to dominate factory and home networks.

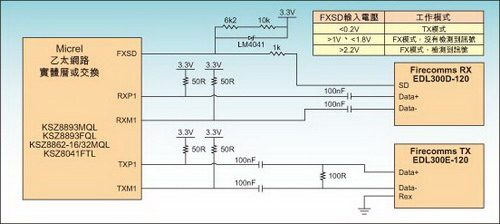

There are a number of different Fiber-Optic Transceivers (FOTs) designed to provide Fast Ethernet (100Mbps) via POF. However, unlike traditional FOTs, such transceivers lack a common interface standard, both electrically and physically. So will this hold back the introduction of Ethernet over POF? Not necessarily, as it depends on the flexibility of existing Ethernet device specifications. Micrel Semiconductor, for example, offers an Ethernet family of multi-port switches and PHYs ideal for POF transceivers. Virtually any differential input can be interfaced to the receiver due to the wide range common-mode and voltage-swing input specifications (50mV pk-pk to Vdd).

Figure 2. Interfacing Ethernet devices to POFtransmitter and receiver

The implementation shown in Figure 2 provides a Fast Ethernet link over POF with a typical reach of 100 meters, comparable to a standard CAT5 solution. Any differences in the signal??s common-mode voltage are removed by AC-coupling the interfaces. An adjustable voltage reference, LM4041, is used to ensure the signal detect input FXSD is in the correct FX mode when a signal is detected (greater than 2.2V) and loss of signal (between 1V and 1.8V). The 10k and 6k resistors are used to adjust the reference voltage across the LM4041 to around 2V. This acts to clamp the FXSD input at 1.3V (Vcc-Vref) when the EDL300D Signal Detect pin (SD) is low (LVCMOS <0.4V). When a signal is present the SD pin is high (>2.4V), thus no current will flow through the reference voltage diode and FXSD will follow the SD pin voltage (>2.4V).

Conclusion

POF technology offers an attractive alternative to traditional glass optical fiber as well as copper for industrial, office, home and automotive networks. It is low cost, light weight, easy and safe to install and EMC immune. However, to become a mainstream alternative to copper cabling in such networks, POF needs to support Ethernet. To achieve this, a variety of different media converter Ethernet solutions are available from Micrel Semiconductor, offering support for 100Base-FX networks as well as legacy 10Base-FL or 100Base- SX applications. These mean that despite a lack of standards, interfacing POF to Ethernet can be a straightforward task.

作者:Mike Jones

Senior Field Application Engineer

Micrel公司

Link:

http://www.eetchina.com/ART_8800489218_480701_TA_eb8ef3a1.HTM

Success Stories

Get more »

Select a product

Feedback

Click for detail »